Inventory definition

/What is Inventory?

Inventory refers to goods ready for sale or the raw materials used to produce them. It is an essential corporate asset, since it is used to generate revenue in many industries. It also acts as a buffer, allowing for the smooth functioning of the production and order fulfillment processes. The four components of inventory are noted below.

Raw Materials Inventory

Raw materials inventory is the source material for a company's manufacturing process. It can literally be "raw" materials that require considerable reconfiguration to become a product (such as sheet metal) or it can be components purchased from a supplier, and which can simply be bolted onto a product that is being assembled.

Work in Process Inventory

Work in process inventory is raw materials that are in the process of being transformed into finished products through a manufacturing process. This can be quite a small amount if the manufacturing process is short, or a massive amount if the item being created requires months of work (such as an airliner or a satellite).

Related AccountingTools Courses

Finished Goods Inventory

Finished goods inventory consists of products that have been fully manufactured, tested, and packaged, making them ready for sale to customers. These goods are stored in warehouses or retail locations until they are sold, shipped, or distributed. Proper management of finished goods inventory is crucial for businesses to meet customer demand without overstocking or facing shortages.

Merchandise Inventory

Merchandise inventory refers to finished goods that a business purchases from suppliers for resale without further processing. This inventory is commonly found in retail stores, wholesalers, and distributors, including products like clothing, electronics, or groceries. Examples of merchandise are clothes sold at a retailer, or tires sold at a local automobile repair shop.

Items Not Included in Inventory

Inventory does not include supplies, which are considered to be charged to expense in the period purchased. Also, customer-owned inventory should not be recorded as inventory owned by the company. Further, supplier-owned inventory located on the premises should also not be recorded as inventory.

Inventory Locations

Inventory can be located in three places, which are:

In company storage. By far the most common of the inventory location types, this is inventory kept in any location that is under the direct control of the business. This may be anywhere at a company facility, in trailers in the company parking lot, in leased warehouse space, and so forth.

In transit. A business technically takes ownership of inventory if the delivery terms from the supplier are FOB shipping point, which means that ownership passes to the buyer as soon as the goods leave the shipping dock of the supplier. At the other end of the delivery pipeline, a business also owns inventory until it reaches the customer's receiving dock if it is shipping under FOB destination terms. However, from a practical perspective, a company does not usually attempt to account for inventory that is either in transit to it or from it.

On consignment. A company may retain ownership of inventory at a retailer or distributor location, with its ownership interest continuing until such time as the inventory is sold. This inventory is much more difficult to track, since it is off-site.

Presentation of Inventory

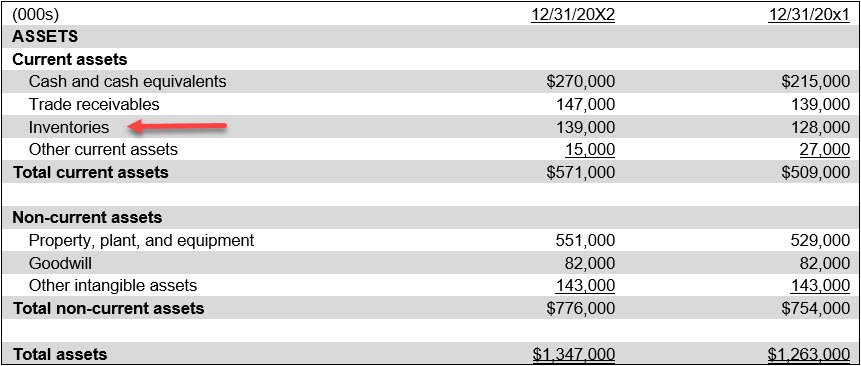

Inventory is considered an asset, and is recorded as such on a company's balance sheet, as a current asset. It is considered to be less liquid than accounts receivable, but more liquid than fixed assets, and so is positioned on the balance sheet between these other line items. The positioning is indicated in the following extract from a balance sheet.

How Valuable is Inventory?

Inventory is one of the least liquid current assets, since it can be difficult to convert into cash. This is especially the case for fashion products that may suddenly out of style, as well as consumer goods with short product cycles. For this reason, lenders may be reluctant to use inventory as collateral for a loan. Given the valuation risk associated with inventory, many organizations monitor it tightly, and sell off excess stocks at the first hint of a loss in value.

Inventory Valuation Activities

Creating a proper valuation to include on the balance sheet requires either a physical count of the inventory to establish the quantities on hand, or a perpetual inventory system that relies on accurate record keeping of every inventory-related transaction. A proper valuation also requires the assignment of a cost to the inventory, which usually involves a costing methodology, such as FIFO costing, LIFO costing, or weighted-average costing.

Related Articles

How to Calculate Ending Inventory

The Difference Between Periodic and Perpetual Inventory Systems